Silky Main Shaft

Silky Main Shaft Specification

- Shape

- Cylindrical

- Features

- High durability, anti-corrosive, precision engineered

- Usage & Applications

- Industrial machinery, textile machinery

- Capacity

- High load-bearing

- Surface Finish

- Smooth

- Lubricating System

- Manual Grease/Oil

- Size

- Customizable

- Drive Type

- Direct Drive

- Noise Level

- Silent Operation

- Diameter

- Custom as per design

- Product Type

- Main Shaft

- Material

- Stainless Steel

- Technology

- CNC Machined

- Power Source

- Mechanical

- Surface Treatment

- Polished

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- Varies as per model

- Color

- Silver

- Packaging Type

- Wooden Box/Standard Export Packaging

- Thread Type

- Metric/Custom

- Tensile Strength

- Up to 750 MPa

- Corrosion Resistance

- Excellent

- Machining Tolerance

- ±0.01 mm

- Hardness

- 58-62 HRC

- End Application Industry

- Textile, Automotive, Mechanical Workshops

About Silky Main Shaft

We are engaged in the procedure of manufacturing and supplying high quality Silky Main Shaft which proceeds to convey the ability to the differential, and afterward eventually, the wheels. It is a mechanical segment for communicating force and turn, normally used to interface different segments of a drive train that cant be associated legitimately in light of separation. This Silky Main Shaft is utilized to communicate power starting with one section then onto the next, or from a machine which produces capacity to a machine which ingests power.

Precision and Performance for Industrial Needs

Engineered with advanced CNC technology, our Silky Main Shaft ensures precision and reliability for various industrial applications. With its superior hardness and tensile strength, the shaft withstands heavy loads and offers seamless integration in textile machinery, automotive setups, and mechanical workshops. Its smooth, polished, and anti-corrosive surface makes it an ideal, long-lasting choice.

Customizable Solutions for Unique Requirements

Every Silky Main Shaft can be tailored in terms of size, diameter, length, and threadingwhether metric or custom. This flexibility, combined with our high machining standards and customizable packaging, enables clients to specify exactly what suits their operational needs, ensuring compatibility and optimal performance in their unique equipment.

FAQs of Silky Main Shaft:

Q: How is the Silky Main Shaft manufactured to ensure precision and strength?

A: The Silky Main Shaft is CNC machined from robust stainless steel, maintaining a tight tolerance of 0.01 mm. This process delivers high dimensional accuracy and a hardness of 5862 HRC, resulting in a shaft that remains durable and dependable under high-load industrial applications.Q: What industries can benefit from using the Silky Main Shaft?

A: It is suitable for use in textile machinery, automotive assemblies, mechanical workshops, and general industrial machinery. Its durability, silent operation, and excellent corrosion resistance make it ideal for demanding environments where reliability and performance are crucial.Q: When should I consider using a custom-sized main shaft?

A: A custom-sized main shaft is recommended when standard dimensions do not meet your machinerys requirements. Customization allows for precise alignment with unique operational setups, improving efficiency and reducing potential maintenance issues.Q: Where is the Silky Main Shaft typically installed within machinery?

A: The main shaft is usually positioned at the heart of rotating assemblies, directly driving components and ensuring smooth torque transmission. Its cylindrical shape and customizable dimensions make it fit directly into various industrial and textile machines.Q: What is the process for ordering and packaging this shaft?

A: Customers can specify size, threading, and packaging preferences (wooden box or standard export packaging) while ordering. Each shaft undergoes quality checks and is securely packed to prevent damage during transit, ensuring it arrives in optimal condition.Q: How is lubrication maintained for the Silky Main Shaft?

A: Lubrication is performed manually using grease or oil, maintaining smooth and noise-free operation while extending the shafts service life.Q: What are the main benefits of using your CNC-machined, stainless steel shaft?

A: The main benefits include high durability, optimal corrosion resistance, silent operation, customizable dimensions, and precision engineeringall contributing to reliable and long-lasting performance in high-demand industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rice Mill Machinery Spare Parts Category

Silky and Whitner Screen (Satake and Buhler)

Material : Stainless Steel/Highquality material

Product Type : Silky and Whitener Screen, Other

Color : Black

Shape : Rectangular Cylindrical

Surface Finish : Smooth and Matte finish

Usage & Applications : Used in Satake and Buhler machines

Standard Whitner Feed Screw

Material : HighGrade Steel

Product Type : Feed Screw, Other

Color : White

Shape : Cylindrical with Grooves

Surface Finish : Smooth

Usage & Applications : For Whitener Applications in Rice Processing

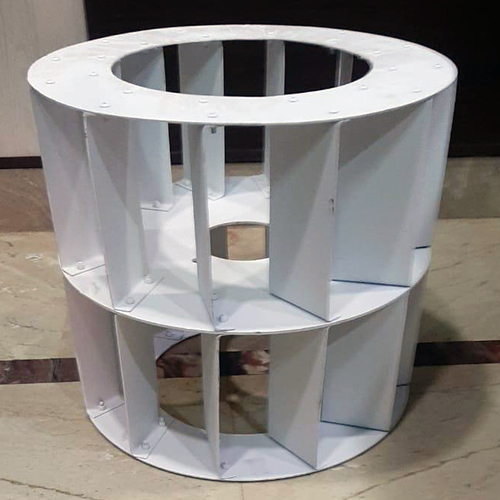

Husker Ampellor

Material : Aluminum

Product Type : Other, Husker Ampellor

Color : White

Shape : Cylindrical

Surface Finish : Matte

Usage & Applications : Agricultural processes Grain removal

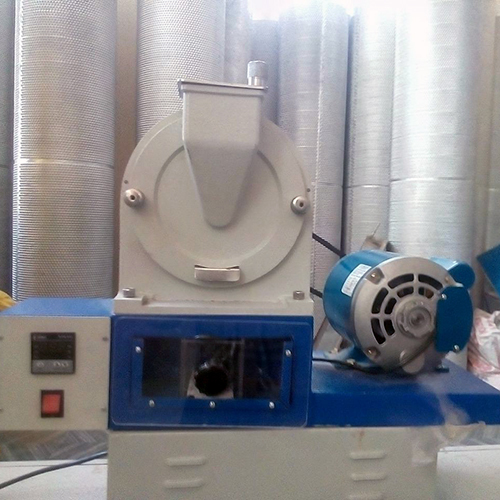

Lab Polisher

Material : Metal

Product Type : Other, Lab Polisher

Color : White and Blue

Shape : Rectangular base with circular polisher

Surface Finish : Smooth

Usage & Applications : Laboratory polishing applications

|

JAIN SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry