Dehusker Rubber Rolles

Dehusker Rubber Rolles Specification

- Drive Type

- Roller Driven

- Noise Level

- Low

- Capacity

- Up to 120 Tons per Month

- Features

- Non-cracking, High Wear Resistance, Long Life

- Size

- 10 x 10; Custom sizes available

- Usage & Applications

- Rice Dehusking, Grain Processing

- Diameter

- 10 Inches

- Shape

- Round

- Surface Finish

- Smooth

- Product Type

- Dehusker Rubber Rollers

- Material

- High Quality Rubber

- Technology

- Hot Pressed and Moulded

- Power Source

- Electric

- Surface Treatment

- Polished

- Dimension (L*W*H)

- 12 x 10 x 4 (approx)

- Weight

- 4.5 kg

- Color

- Yellow

- Service Life

- Up to 6 Months

- Packing Type

- Carton Box / Wooden Box

- Performance

- Consistent Dehusking Quality

- Moisture Absorption

- Low

- Compatibility

- Suitable for all standard rice dehusker machines

- Core Material

- Aluminum

- Minimum Order Quantity

- 10 Pieces

- Bonding Strength

- High

- Abrasion Resistance

- Excellent

- Hardness (Shore A)

- 85±5

- Application Method

- Install on Dehusker Machine

- Heat Resistance

- Up to 90°C

Dehusker Rubber Rolles Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 10 Days

About Dehusker Rubber Rolles

Versatile Application and Direction of Use

Ideal for rice dehusking and grain processing, these rubber rollers provide reliable performance in agricultural mills and industrial processing units. Installation is straightforward: simply fit onto standard dehusker machines using the roller-driven method. Application areas span rice mills, grain processing plants, and food manufacturing facilities. Also suitable for custom machinery where efficient dehusking is needed. For optimal results, follow specified installation guidelines and ensure regular inspection for prolonged service life.

Certifications, Payment Terms, and Domestic Market

Our dehusker rubber rollers are handed over with full compliance to industrial quality certifications, assuring buyers of safety and reliability upon arrival. While the asking price is competitive, payment terms are flexible and tailor-made for large orders. We focus on serving India's main domestic market by partnering with rice processors, traders, and manufacturers. Custom orders, prompt delivery, and secure packaging make us a preferred supplier for businesses demanding long-lasting value and premium support.

FAQ's of Dehusker Rubber Rolles:

Q: How do I install the Dehusker Rubber Rollers on my machine?

A: Installation is easy-mount the rollers onto your dehusker machine using the recommended roller-driven method. Ensure all fastenings are secure for optimal performance and safety.Q: What makes these rubber rollers stand out compared to others in the market?

A: These rollers feature rarefied high-quality rubber with ace heat and abrasion resistance, minimal moisture absorption, and a finely polished finish. Their robust aluminum core and high bonding strength contribute to consistent dehusking and long service life.Q: When should I replace the Dehusker Rubber Rollers?

A: Each roller offers a service life of up to six months. Replace them as needed to maintain maximum dehusking quality and prevent machine downtime, especially with continuous use.Q: Where can these rollers be used besides rice dehusking?

A: Apart from rice mills, these rollers are suitable for grain processing plants, food production facilities, and custom machinery that requires reliable dehusking or peeling operations.Q: What payment and delivery options are available for bulk orders in India?

A: We offer flexible payment terms and competitive asking prices for bulk orders. Products are handed over securely and delivered promptly across India's main domestic markets, with customized packing options on request.Q: How does the low noise level benefit my processing operation?

A: Low noise during operation improves workplace comfort, reduces stress, and meets modern industrial safety standards-making these rollers highly efficient for large-scale grain dehusking.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rice Mill Machinery Spare Parts Category

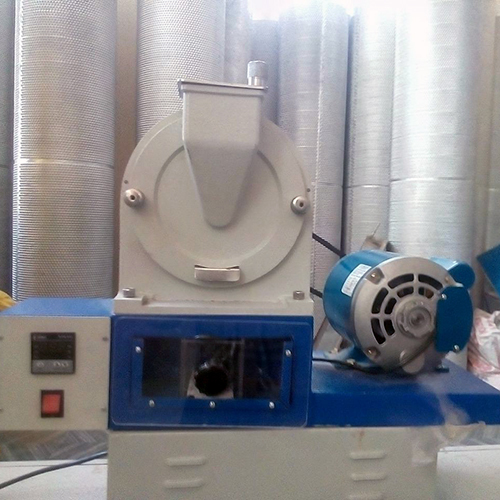

Lab Husker

Color : Blue

Material : Mild Steel

Shape : Rectangular base funnelshaped hopper

Product Type : Other, Lab Husker

Surface Finish : Powder Coated

Usage & Applications : Laboratory Rice Processing

Lab Polisher

Color : White and Blue

Material : Metal

Shape : Rectangular base with circular polisher

Product Type : Other, Lab Polisher

Surface Finish : Smooth

Usage & Applications : Laboratory polishing applications

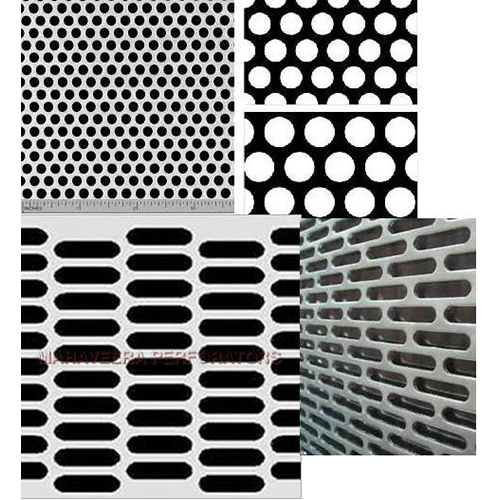

Round Hole Long Hole Screen

Color : Black

Material : Metal

Shape : Rectangular

Product Type : Other, Round Hole Long Hole Screen

Usage & Applications : Filtering sieving separation in industrial processes

Whitner Bottom Ring

Color : White

Material : Synthetic Material

Shape : Circular

Product Type : Whitner Bottom Ring, Other

Surface Finish : Smooth

Usage & Applications : Used in industrial machinery

|

JAIN SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry